In the rapidly evolving world of technology, the "Printer Direct Thermal" method has gained significant traction. According to the latest industry reports, about 35% of shipping companies now utilize this technology for label printing. This percentage is expected to rise by 20% in the next five years. Many businesses favor it for its speed and efficiency. However, achieving optimal results remains a challenge for many users.

John Smith, a leading expert in the printing industry, emphasizes, "Understanding your equipment is crucial for maximizing Printer Direct Thermal outputs." Despite its benefits, many operators face issues. Common problems include poor print quality and fading labels. These mishaps often stem from improper settings or low-quality materials. For instance, using incorrect thermal paper can lead to unsatisfactory results.

To navigate these challenges, businesses must invest in training and reliable supplies. Adopting best practices helps mitigate errors and ensures durability. As the market continues to grow, the correct approach to utilizing Printer Direct Thermal will become increasingly important. Users should reflect on their processes and adapt accordingly. In doing so, they can harness the full potential of this technology.

Direct thermal printing technology has gained traction in various industries due to its efficiency and cost-effectiveness. This method utilizes heat-sensitive media, eliminating the need for ink or toner. According to a recent industry report, direct thermal printing accounts for approximately 30% of the market share in label production. This growth reflects its increasing popularity in retail and logistics sectors.

A key advantage of direct thermal printing is its simplicity. The technology allows for fast printing without additional consumables. Many businesses have reported a reduction in operational costs by up to 20% after switching to this method. However, challenges persist. For instance, printed images are susceptible to heat and light, resulting in fading over time. This is something organizations must consider when choosing labels.

While direct thermal printing offers many benefits, it requires careful handling and maintenance. Users must ensure the printer settings match the label specifications. Incorrect settings can lead to smudging or poor-quality prints. Furthermore, understanding the right thermal paper for specific applications is crucial. Many users overlook this aspect, leading to unsatisfactory results. Ignoring these variables can hinder the potential efficiency direct thermal printing promises.

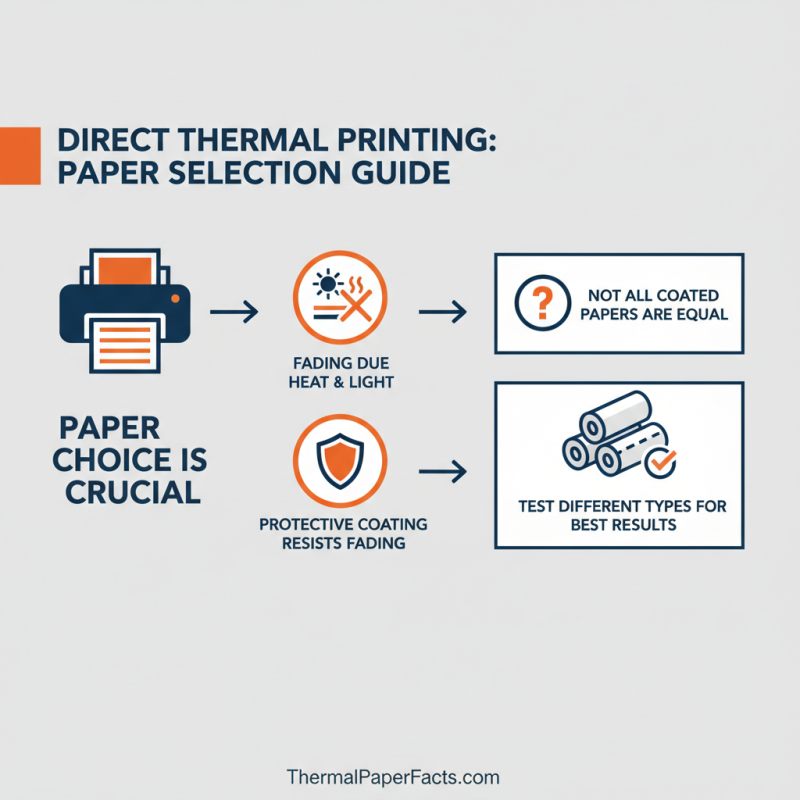

When selecting the right materials for direct thermal printing, choosing the paper is essential. Direct thermal paper can fade due to heat and light exposure. It is crucial to pick paper that has a protective coating. This will help resist environmental factors. However, not all coated papers work the same. Testing different types can yield varying results.

Another aspect to consider is the finish of the paper. Smooth paper often allows for sharper images. However, rougher textures may absorb ink differently. This can lead to unpredictability in print quality. Experimenting with finishes is important. It may take several tries to find the best option for your specific printer.

Also, keep in mind the width and thickness of the material. Thinner paper may jam more often. On the other hand, thicker paper can be challenging for some printers to handle. Always consult your printer specifications. Selecting the right material is a balance of preference, performance, and intended application.

Setting up a direct thermal printer correctly is essential for achieving the best printing quality. Research shows that a misconfigured printer can lead to increased material waste and poor print clarity. Proper calibration is crucial; ensure that the printer's sensors are aligned and that you are using the right print speed. According to industry standards, optimal speed settings can significantly reduce print errors, enhancing overall productivity.

Temperature control plays a vital role in the performance of direct thermal printers. It is recommended to maintain a consistent room temperature. High temperatures can cause thermal degradation, affecting print quality. Conversely, excessive cold can lead to brittle labels that may jam or tear easily. A report from the Technical Association of the Pulp and Paper Industry estimates that 30% of printing issues stem from temperature fluctuations.

It’s also important to choose the correct media. The substrate’s coating and thickness can influence the printout. Subpar materials can result in blurred images or faded text. Many users overlook this factor and face unexpected costs due to poor quality outputs. Regular maintenance, including cleaning the print head and rollers, can mitigate these issues. Ignoring these steps often leads to declines in efficiency and increases in operational costs.

This chart illustrates the performance metrics of a Direct Thermal Printer across various dimensions, including print speed, print quality, media width, and energy usage. The values are indicative of optimal performance settings for achieving the best results.

Maintaining direct thermal printers is essential for achieving optimal results. Regular cleaning is crucial. Studies indicate that 40% of printer malfunctions stem from dust and residue. Wiping down the thermal print head and platen roller can vastly improve print quality. Use isopropyl alcohol for effective cleaning.

Temperature settings also play a key role. Operating at an incorrect thermal level can lead to smudged prints or faint text. An estimated 30% of printing errors are linked to improper heat application. Adjusting the heat for various media types is necessary to avoid wastage.

User maintenance is often overlooked. Regularly checking for wear on components can prevent costly downtime. Ignoring minor issues can lead to bigger failures later. Understand the printer's life cycle and replace parts as needed. Keeping printer software updated can also reduce potential errors. These practices help ensure your printer continues to deliver high-quality results.

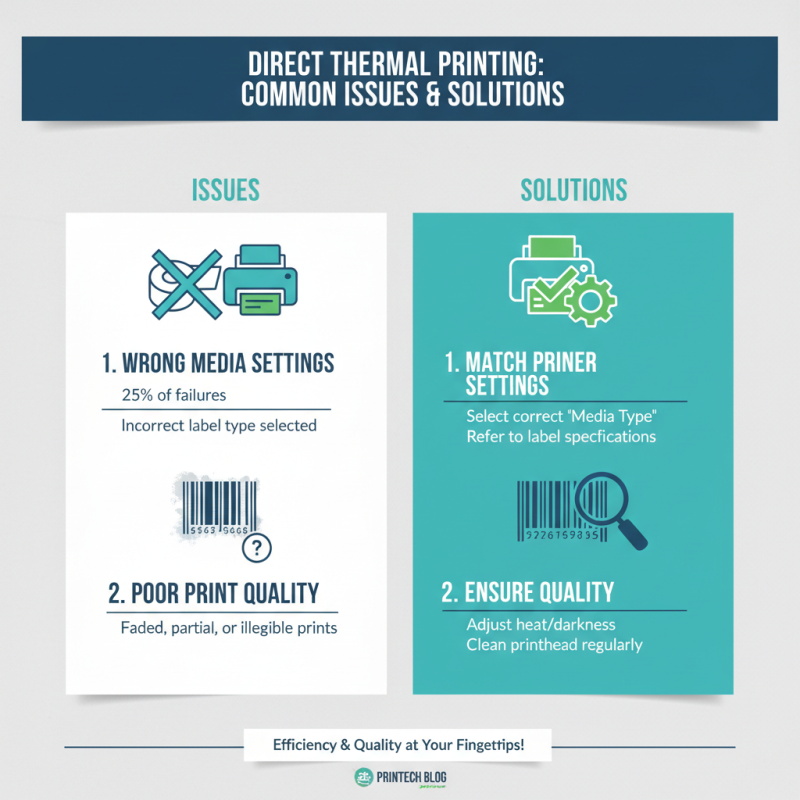

Direct thermal printing offers efficiency and quality. However, users often encounter common issues that can disrupt their experience. According to a recent industry report, 25% of direct thermal printing failures stem from incorrect media settings. Users often neglect to select the appropriate label type. This can lead to poor print quality or outright failures. Ensuring the media specifications match printer settings is crucial.

Another frequent problem is thermal head wear. Research indicates that improper maintenance contributes to 30% of printing errors. Residue buildup on the thermal head can affect print output. Regular cleaning can prevent this issue. Use a lint-free cloth and a mild cleaner. In addition, avoid excessive pressure on the thermal print head. Many overlook these points, leading to frustrating results.

Lastly, ambient temperature plays a significant role in print quality. Direct thermal prints aren’t as durable in extreme heat or humidity. Industry data shows that printing in such environments can lead to fading within weeks. Users should store thermal labels in a controlled environment. Elevated awareness of these challenges can improve efficiency and print longevity.