In the dynamic world of product packaging, selecting the right paper labels can significantly impact branding, customer perception, and operational efficiency. According to a recent report by Smithers Pira, the global market for paper labels is projected to reach $40 billion by 2024, highlighting a growing demand across various industries. With environmental sustainability becoming a paramount concern, the paper label sector has seen innovations in eco-friendly materials and printing technologies, making it essential for businesses to stay informed about the latest options available.

Industry expert Dr. Emily Carter, a leading figure in packaging research, emphasizes the importance of choosing the right paper label: "The right label not only enhances a product's appearance but also communicates its quality and sustainability—essential elements in today's competitive market." As consumer preferences continue to evolve, the factors affecting label choices include material, adhesive quality, printability, and regulatory compliance, each of which plays a crucial role in ensuring that products stand out on shelves while meeting industry standards.

In this guide, we will delve into the top 10 tips for selecting the best paper labels tailored to your specific needs, helping you navigate the complexities of label selection in a diverse marketplace. Understanding these aspects can lead to smarter choices that enhance your brand's visibility and responsibility in an ever-changing consumer landscape.

When selecting paper labels, the first step is to clearly identify your labeling requirements and goals. Consider the purpose of the labels: Are they for product packaging, shipping, or organization? Understanding how the labels will be used can significantly influence the type of paper and adhesive you choose. For instance, labels for products meant for retail need to be visually appealing and adhere well to various surfaces, while shipping labels might prioritize durability and clarity over aesthetics.

Another critical aspect to consider is the information that needs to be displayed on the labels. This includes the size, font, and amount of text required to convey necessary details effectively. For instance, if you need to include barcodes or QR codes, ensure that the label size accommodates these elements without compromising on readability. Additionally, think about the environment the labels will be exposed to; if they will be subjected to moisture, heat, or other challenging conditions, selecting a more robust paper type can enhance their performance and longevity. By thoroughly assessing your labeling needs, you can make more informed decisions that align perfectly with your operational goals.

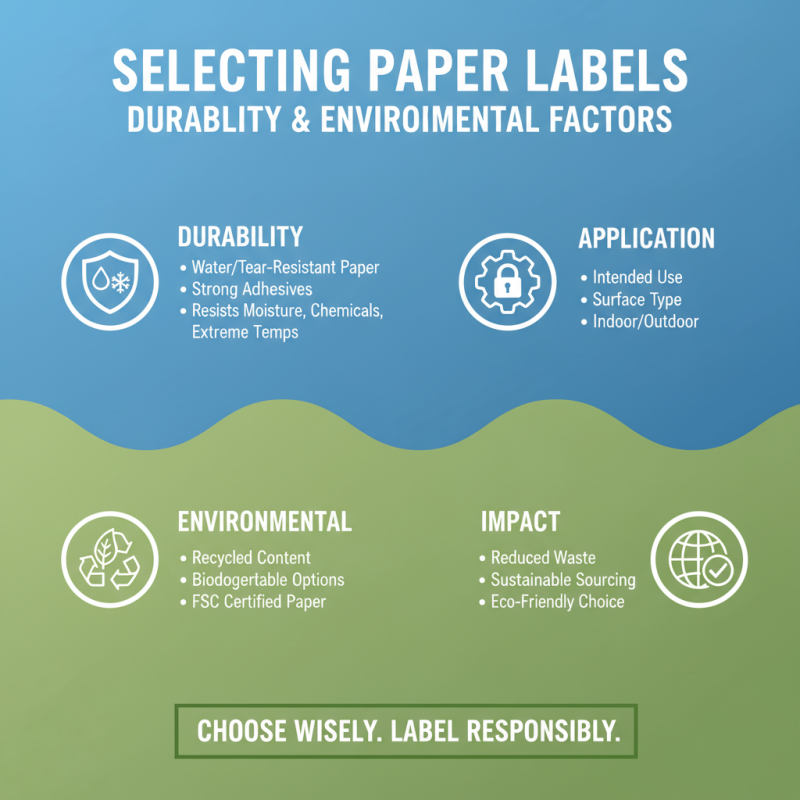

Here is a visual representation of important factors to consider when choosing paper labels. These tips can help guide you in meeting your labeling requirements and goals.

When it comes to choosing the right paper labels, understanding the different types available is crucial. The most common varieties include matte, glossy, and textured labels. Matte labels provide a non-reflective surface that lends a sophisticated look, making them ideal for upscale products. Glossy labels, on the other hand, enhance colors and details thanks to their shiny finish, which is excellent for eye-catching designs. Textured labels add a tactile element, perfect for artisanal goods that seek to communicate quality and craftsmanship.

When selecting paper labels, consider the purpose and environment they will be used in. For instance, if the labels are to be used in a humid setting, water-resistant options may be necessary to maintain durability. Additionally, think about the printing method you plan to use—some labels perform better with inkjet printers, while others may be better suited for laser printing.

It’s also important to consider the adhesive properties of the labels. Some require permanent adhesion, while others may need to be removable. Choosing the right adhesive can affect both application and removal, making it essential to align the label type with your specific requirements. By keeping these tips in mind, you can navigate the variety of paper labels to find the perfect fit for your needs.

When selecting paper labels, considering adhesive options for specific surfaces is paramount to ensure optimal performance and durability. Different surfaces require distinct adhesive properties to guarantee that labels adhere properly and remain intact over time. For instance, the 2023 Labeling Industry Global Market Study indicates that over 50% of label failures are attributed to inadequate adhesive choice. A varying degree of surface energy—such as smooth glass versus porous cardboard—demands corresponding adhesive formulations for maximal bonding strength.

Moreover, understanding the intended application of the label can further inform adhesive selection. Research indicates that permanent adhesives are ideal for applications requiring long-lasting adhesion, while removable adhesives serve well for temporary labeling needs. For example, surfaces encountered in refrigerated environments might benefit from cold-temperature adhesives, which maintain performance under varying temperature conditions. Industry reports emphasize that choosing the right adhesive not only enhances the longevity of the labeling solution but also maintains brand integrity by ensuring that labels stay intact through various handling and processing phases.

When selecting paper labels, it's crucial to consider both durability and environmental factors to ensure they meet your specific needs. Durability often depends on the materials used and the intended application of the labels. If the labels will be exposed to moisture, chemicals, or extreme temperatures, opting for water-resistant or tear-resistant paper can significantly extend their lifespan. Additionally, labels with strong adhesive properties can help maintain their integrity in demanding conditions, ensuring that they remain affixed where needed without risking peeling or fading.

Equally important is the environmental impact of the labels you choose. With increasing awareness of sustainability, selecting paper labels made from recycled materials or that are biodegradable can contribute to reducing your ecological footprint. Look for labels that are not only functional but also offer eco-friendly certifications, indicating that they are produced with minimal environmental harm. By prioritizing both durability and environmental factors, you can make an informed choice that aligns with your practical requirements while also supporting sustainable practices.

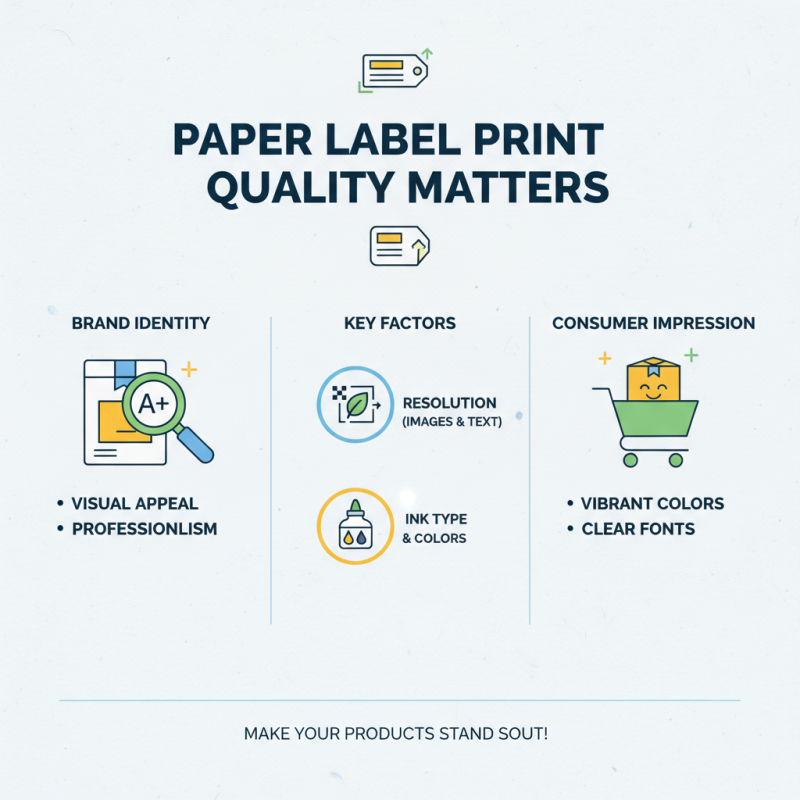

When selecting paper labels, print quality plays a crucial role in establishing your brand identity and ensuring that your products stand out. High-quality print not only enhances the visual appeal of your labels but also conveys professionalism and attention to detail. To achieve the desired print quality, consider the resolution of images and text, as well as the type of ink used. Opting for vibrant colors and clear fonts can significantly impact the first impression consumers have of your product.

Furthermore, it is essential to understand the materials that will support your print needs. The choice of paper can influence the way ink adheres and appears. For instance, a glossy finish can enhance color saturation, while a matte surface offers a more sophisticated look. Additionally, ensure that the labels are compatible with your printing technology, whether it’s digital or offset printing. By prioritizing print quality in your label selection, you not only promote your business effectively but also create a lasting impression that resonates with your target audience.