In the fast-evolving world of printing technology, selecting the right Thermal Ribbon Roll can significantly impact the efficiency and quality of your business operations. According to industry expert John Smith, a leading consultant in thermal printing solutions, “Choosing the right thermal ribbon is not just about compatibility; it’s about ensuring longevity and exceptional print quality.” As businesses and manufacturers navigate the complexities of various ribbon types, understanding the features and benefits of Thermal Ribbon Rolls becomes paramount.

Thermal ribbons come in several types, each designed for specific applications. From wax to resin, the right choice can enhance your output while reducing costs. With the ever-increasing demand for high-quality printed materials, it’s essential for businesses to stay informed about which Thermal Ribbon Roll best suits their unique needs. In this article, we will delve into key factors to consider when selecting a thermal ribbon, ensuring your choice aligns with both your operational requirements and budgetary constraints—ultimately leading to improved productivity and customer satisfaction.

Thermal ribbon rolls are essential components in thermal printing technology, widely utilized in sectors where durable and high-quality labeling is crucial. These rolls consist of a polymer-based ribbon coated with wax, resin, or a combination of both, creating clear and enduring prints. As businesses increasingly rely on barcodes, receipts, and labels for inventory and identification processes, understanding the functionality of thermal ribbon rolls becomes imperative. They allow printers to transfer images onto various materials, providing flexibility and efficiency in different applications, from shipping labels to product tags.

Selecting the right thermal ribbon roll for your business involves considering several factors, including the type of printer in use, the materials being printed on, and the specific environmental conditions of operation. Depending on the application, a wax ribbon may suffice for standard printing needs, while a resin ribbon might be necessary for harsher environments requiring enhanced durability and resistance to smudging and scratching. By aligning these criteria with the unique demands of their operations, businesses can ensure optimal performance and longevity of their thermal printing systems.

| Feature | Description | Recommendation |

|---|---|---|

| Material | Typically made from wax, resin, or a combination of both. | Choose based on your printing requirements and durability needs. |

| Width | Available in various widths to suit different label sizes. | Match the ribbon width with the label size for optimal usage. |

| Length | Typically ranges from 74 meters to 600 meters. | Consider the print volume to select the appropriate length. |

| Compatibility | Must be compatible with your thermal printer model. | Check printer specifications before purchasing ribbons. |

| Print Quality | Affects the clarity and durability of printed labels. | Invest in high-quality ribbons for important labels. |

| Application | Used for shipping, product labeling, barcodes, and more. | Define your use case to select the best ribbon type. |

When selecting thermal ribbon rolls for your business, understanding key features is crucial to ensure optimal performance and efficiency. One of the most important factors is the ribbon material, which typically includes wax, resin, or a combination of both. According to the Smithers Pira report, the global market for thermal transfer ribbons is expected to grow at a CAGR of 4.5% from 2021 to 2026, primarily driven by the demand for high-quality printing solutions. Wax ribbons are typically more affordable and ideal for general-purpose printing on paper labels, while resin ribbons provide superior durability and resistance to chemicals, making them suitable for harsher environments.

Another critical consideration is the ribbon width and length, which must match your printer’s specifications to avoid jams and ensure print quality. According to a study by the Initiative for a Competitive Inner City (ICIC), businesses can lose up to 20% of their operational efficiency due to improper inventory management, including mismatched supplies like thermal ribbons. Additionally, invest in understanding the ink formulation, as this affects print quality and longevity. By paying attention to these fundamental features, you can make an informed choice that aligns with your business needs and enhances operational efficiency.

When selecting the best thermal ribbon for your business, understanding the leading brands in the market is crucial. As of 2025, five brands have emerged as top contenders, each offering unique features suited to various applications. Zebra Technologies is renowned for its high-quality printing capabilities and a wide range of ribbon options, ideal for diverse industrial needs. Their focus on durability ensures that labels remain clear and intact, even in harsh environments.

Another prominent brand is Brady Corporation, which specializes in customizable thermal ribbons designed for specialty applications. They are particularly favored in sectors such as healthcare and manufacturing, where label compliance and clarity are paramount. Additionally, TSC Printers is gaining attention for its cost-effective solutions without compromising quality. Their ribbons provide smooth performance and vibrant color output, making them ideal for businesses seeking value. Finally, Epson stands out for its innovative technology and eco-friendly ribbon options, appealing to companies that prioritize sustainability. By considering these top brands, businesses can make informed decisions that enhance their printing efficiency and overall productivity.

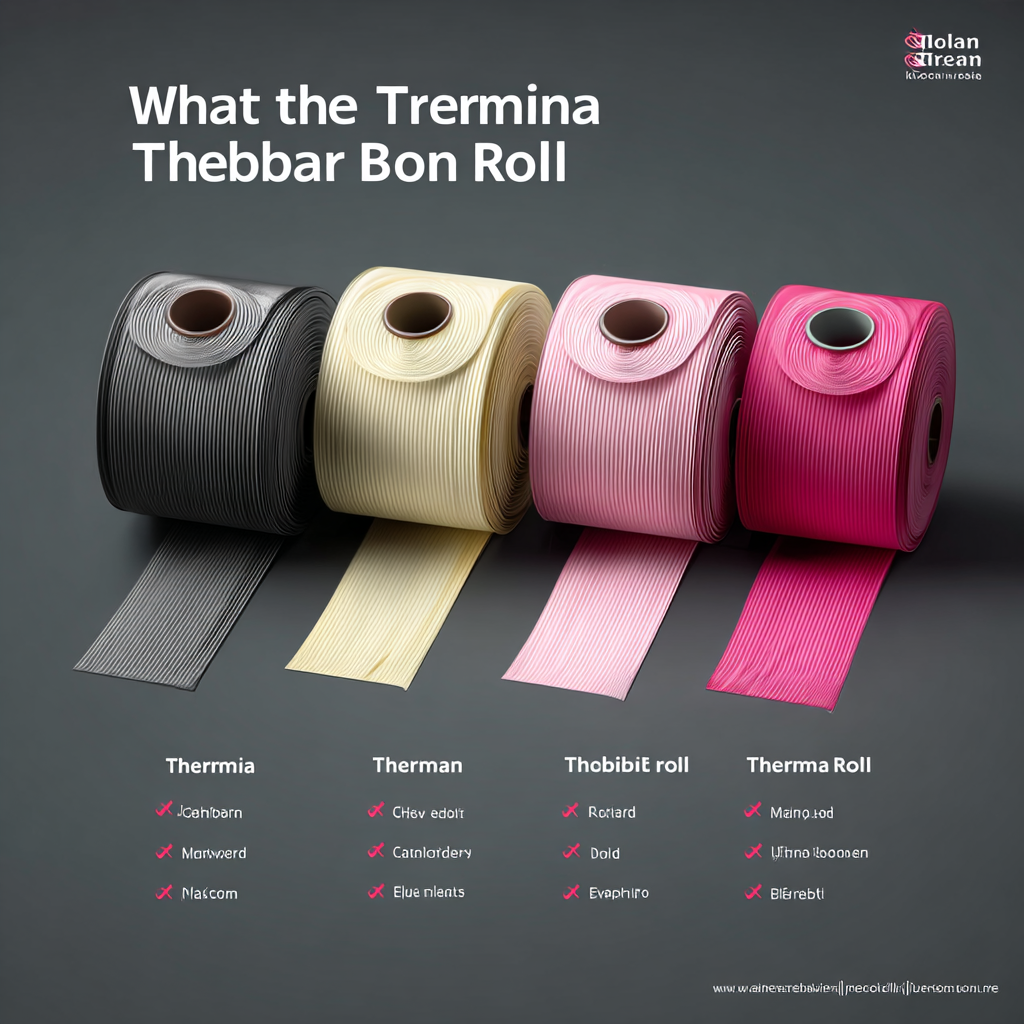

When selecting thermal ribbon rolls for your business, understanding the difference between wax and resin thermal ribbons is crucial. Wax ribbons, known for their affordability, are ideal for printing on paper labels, where durability is not the highest priority. According to a 2022 industry report from Smithers Pira, wax ribbons account for over 60% of the thermal ribbon market due to their cost-effectiveness and ability to print at high speeds. They produce sharp images and are optimal for short shelf-life applications, making them suitable for retail labeling and logistics.

On the other hand, resin thermal ribbons offer higher durability and resistance to various environmental factors such as moisture, UV light, and chemicals. Data from the same report shows that the resin ribbon market is experiencing a growth rate of 8% annually, driven by increasing demand for labels in sectors like pharmaceuticals and electronics, where longevity and quality are essential. These ribbons are more expensive but provide superior print quality and longevity, making them a worthwhile investment for businesses requiring durable labels.

When choosing between wax and resin, consider the specific needs of your application, as the right thermal ribbon can significantly impact your printing efficiency and product presentation.

To optimize thermal ribbon usage for cost efficiency and quality, businesses should consider several factors that directly impact their operations. According to a report by Smithers Pira, the global thermal ribbon market is expected to grow significantly, projecting a CAGR of approximately 4.6% from 2022 to 2027. This growth emphasizes the need for businesses to maximize their investments in thermal ribbon technology. Choosing the right thermal ribbon type—wax, resin, or a combination—based on the application can enhance printing performance and reduce costs in the long run.

One effective strategy for optimizing thermal ribbon usage is proper inventory management. Research by the Printing Industries of America suggests that organizations that implemented a systematic inventory control system reported a reduction in waste by up to 30%. By accurately predicting demand and maintaining optimal stock levels, businesses can minimize excess ribbon inventory that may lead to obsolescence. Additionally, training staff on proper printing techniques and maintaining printers can further improve ribbon life and printing quality, leading to significant cost savings while ensuring high-quality output in their labeling and packaging processes.