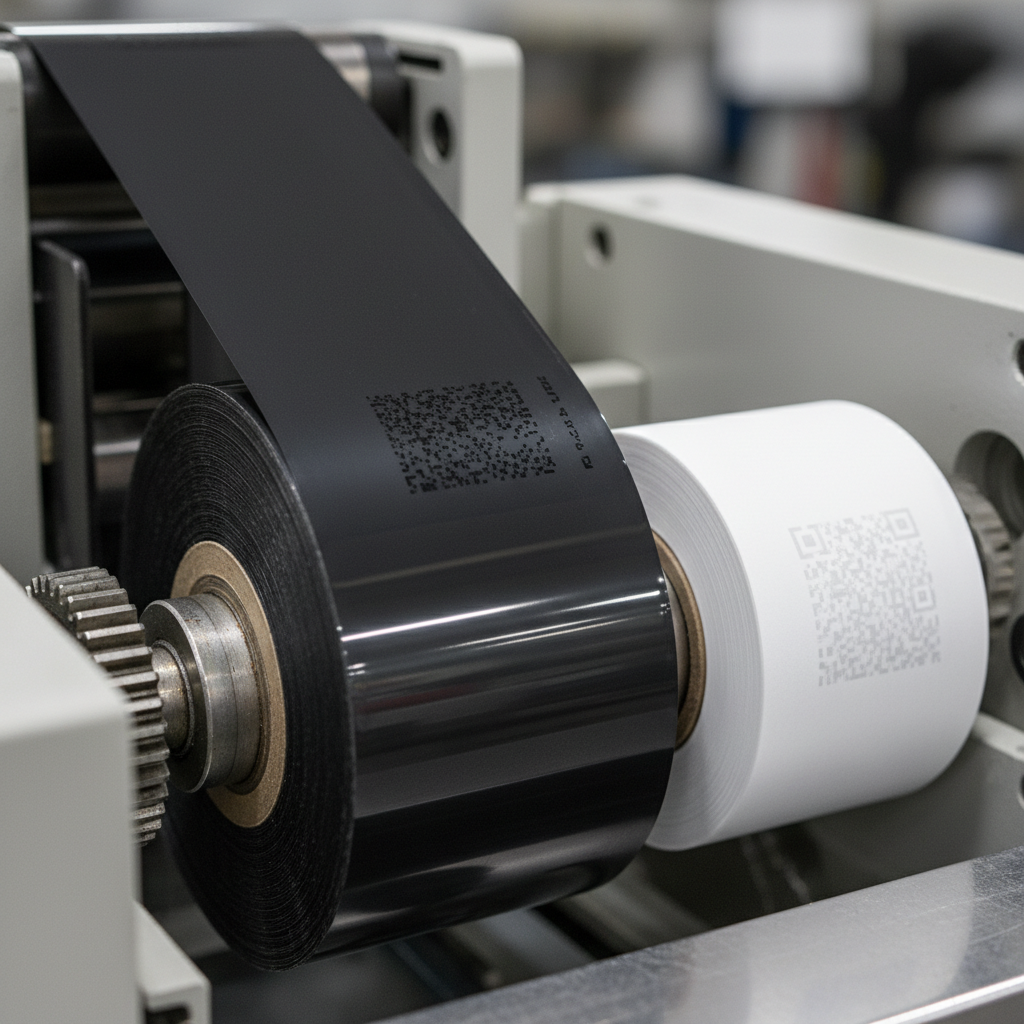

Choosing the right thermal ribbon roll is crucial for optimizing printing operations across various industries. According to a report by Smithers Pira, the global demand for barcode and thermal printing is projected to reach $35.2 billion by 2025, reflecting an increasing reliance on efficient labeling and packaging solutions. In this context, the selection of the appropriate thermal ribbon not only impacts print quality but also influences overall productivity and cost-effectiveness.

Thermal ribbon rolls come in different types, materials, and specifications, catering to various printing technologies and applications. A study published in the Journal of Printing and Media Technology Research highlights that selecting the right thermal ribbon can enhance print durability and resistance to harsh environmental conditions, which is particularly vital for industries like logistics, healthcare, and retail. As businesses strive for greater efficiency and sustainability, understanding the nuances of thermal ribbon technology becomes imperative for making informed purchasing decisions that align with specific operational needs.

Choosing the right thermal ribbon is essential for optimizing printing quality and efficiency. There are three primary types of thermal ribbons: wax, resin, and composite. Each type serves different applications based on the surface of the label, durability requirements, and environmental factors. According to a report by Smithers Pira, the global thermal transfer ribbon market is projected to reach $1.3 billion by 2025, underscoring the importance of making informed decisions in selecting the appropriate ribbon type to meet various printing demands.

Wax ribbons are typically used for standard label printing on paper substrates, providing clear and crisp images with moderate resistance to smudging. This type of ribbon is cost-effective and widely employed in industries such as retail and logistics. On the other hand, resin ribbons offer much higher durability and are ideal for printing on synthetic materials. They are resistant to chemicals, heat, and abrasions, making them suitable for applications in healthcare and manufacturing sectors. Composite ribbons, combining both wax and resin properties, provide a versatile solution for mid-range applications where both affordability and durability are required. Selecting the right thermal ribbon is critical and can significantly impact the quality of printed materials in various business environments.

| Ribbon Type | Best Use Case | Durability | Cost |

|---|---|---|---|

| Wax | General-purpose label printing | Low | Low |

| Resin | High-durability labels | High | High |

| Composite | Versatile applications | Medium | Medium |

When choosing the right thermal ribbon roll for your printing needs, it's essential to evaluate your specific printing requirements, focusing on resolution, speed, and durability. The resolution is crucial, especially if you're printing detailed images or barcodes. Higher resolution ribbons produce clearer text and graphics, making them ideal for applications like labels or tags that require precision.

Speed is another critical factor to consider. If you're printing in high volumes, you'll need a ribbon that can keep up with your printer’s performance. Fast printing ribbons can significantly enhance efficiency and reduce wait times, enabling smoother workflows in busy environments.

Tips: Always test ribbons before committing to a larger purchase; this ensures compatibility with your printer and meets your quality expectations. Additionally, consider the environmental conditions where your printed materials will be used. For instance, if the labels will be exposed to moisture or chemicals, opting for a more durable ribbon can safeguard against wear and fading.

When selecting the right thermal ribbon roll for your printing needs, it's crucial to consider the specifications of your printer. Each printer model has unique requirements regarding ribbon size, type, and compatibility. For instance, some printers may require a specific width for optimal print clarity, while others may function better with particular ribbon formulations, such as wax, resin, or a combination of both. Understanding these needs will enable you to achieve the best print quality and durability for your labels.

Additionally, the format of the labels you plan to print plays a significant role in your ribbon choice. If you're printing shipping labels or barcode labels, the ribbon's thermal transfer properties must match the label materials to ensure proper adhesion and longevity. Taking the time to match your thermal ribbons with your printer’s specifications and the formats of the labels can significantly improve your printing efficiency and reduce costs associated with poor-quality prints.

When selecting a thermal ribbon roll for your printing needs, it is vital to consider the environmental factors that can impact performance. Temperature fluctuations can significantly affect the adhesion of the ribbon to the substrate. High temperatures can cause ribbons to smudge or degrade, while low temperatures might inhibit proper transfer and result in faded images or text. Therefore, it is essential to evaluate the operating conditions of your printing environment and choose a ribbon designed to perform optimally within those temperature ranges.

Surface compatibility is another critical factor in making an informed choice. Different substrates, such as paper, polyester, or polypropylene, require specific types of thermal ribbons to ensure proper transfer and durability. For instance, a wax-based ribbon may work well on standard paper but may not adhere appropriately to synthetic surfaces, leading to poor quality prints. Understanding the characteristics of the material you're printing on will guide you in selecting the right thermal ribbon that ensures clear, long-lasting images while minimizing print errors.

When selecting the right thermal ribbon roll for your printing needs, assessing cost-effectiveness can significantly impact your overall expenditure. Longevity is a key factor; the average thermal ribbon has a lifespan ranging from 6 months to 2 years, depending on usage. A report from Smithers Pira indicates that companies can achieve up to 30% in cost savings by opting for longer-lasting ribbons that align with their printing volume. Bulk purchasing also plays a vital role in enhancing cost-effectiveness. Many suppliers offer substantial discounts on larger orders, enabling businesses to reduce individual unit costs and ensure they have a steady supply on hand.

**Tips:** When considering bulk purchases, always evaluate your actual usage and storage capabilities to avoid wastage. Additionally, comparing different brands and their specifications can help you select ribbons that provide the best performance relative to their price. Remember, the right ribbon can minimize downtime and improve print quality, translating into both immediate savings and long-term benefits.

In today's competitive market, understanding the nuances of thermal ribbon options can lead to more informed decisions. Organizations committed to maximizing their printing efficiency should consider factors such as compatibility with existing printers and the specific requirements of their applications. Reports indicate that aligning your ribbon specifications with your printer's capabilities can lead to a 20-40% reduction in operational issues, further emphasizing the importance of these considerations.