In the ever-evolving landscape of networking infrastructure, the importance of choosing the right Ethernet Cable Labels cannot be overstated. According to a recent report by the Networking Industry Association, nearly 70% of IT professionals agree that effective labeling has significantly enhanced their ability to manage network cables and troubleshoot issues swiftly. As the complexity of networks continues to increase, the demands for clarity and organization in cable management have become paramount.

Expert David Hardwick, a veteran in the networking sector, emphasizes, “Without proper Ethernet Cable Labels, even the best cables can become the source of frustration and inefficiency.” His insights reflect a growing recognition within the industry that labeling is not just an administrative task but a critical component for maintaining high-performance networks. By opting for high-quality Ethernet Cable Labels, organizations can streamline their operations, reduce the risk of errors during installation, and ensure that technicians can quickly identify connections during maintenance.

As businesses invest in faster and more reliable networking solutions, the strategic selection of Ethernet Cable Labels becomes essential not only from a practical standpoint but also for enhancing overall productivity. This guide aims to explore the key factors to consider when selecting the most suitable labels to meet your specific networking needs, ensuring that your infrastructure remains efficient, organized, and future-ready.

In today's fast-paced digital world, the importance of Ethernet cable labels cannot be overstated. These labels provide essential information that allows network administrators to easily identify and manage their connections. Proper labeling not only helps in organization but also significantly reduces the time needed for troubleshooting and maintenance. When cables are labeled accurately, it becomes straightforward to trace back and resolve network issues without unnecessary disruptions.

To make the most of Ethernet cable labels, consider the following tips: First, use clear and concise wording to indicate the purpose of each cable, such as "Router to Switch" or "Camera Feed." This clarity will prevent confusion, especially in environments with multiple cables. Second, opt for labels that can withstand wear and tear, particularly in high-traffic areas where cables might be frequently handled. Choosing durable materials ensures that the labels remain legible over time.

Lastly, maintaining an updated documentation system alongside your cable labels is crucial. Keep a visual map or a database that correlates with your labels, providing a comprehensive overview of your network setup. This practice can save precious time when modifications are necessary, allowing for efficient updates without the hassle of identifying disconnected or mislabeled cables.

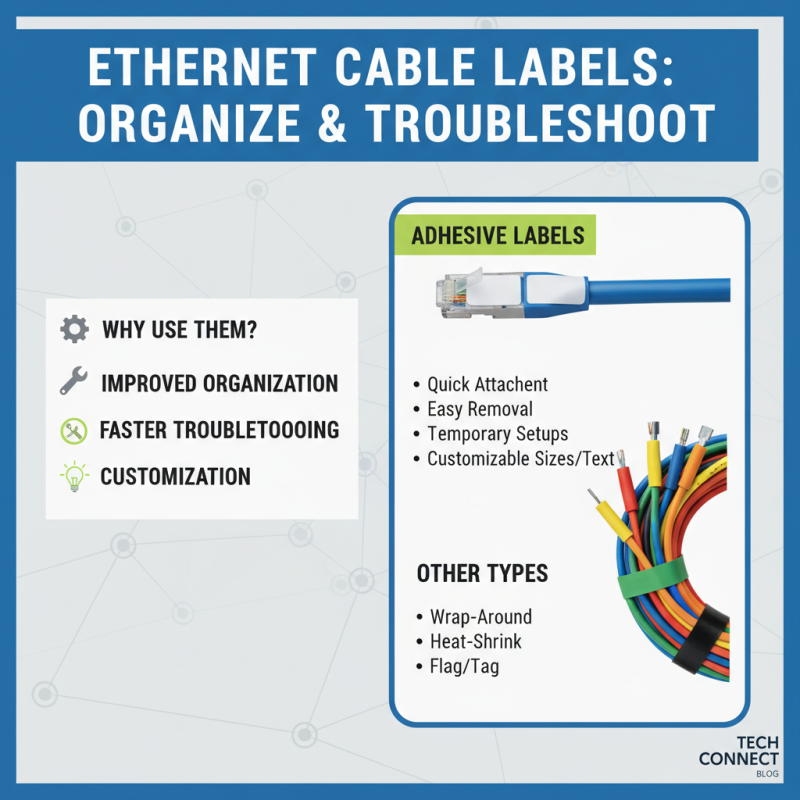

When it comes to networking, using the right Ethernet cable labels can significantly improve organization and troubleshooting capabilities. Different types of Ethernet cable labels cater to various needs and environments. For instance, adhesive labels are available for quick attachment and easy removal, making them perfect for temporary setups or environments where cables may be frequently changed. These labels often come in various sizes and can be printed using standard label makers, allowing for customization that fits specific requirements.

Another popular option is heat-shrink labels, which provide a more permanent labeling solution. These labels are applied to the cable and shrunk using heat, forming a tight fit that can withstand environmental factors like moisture and dust. This type of label is particularly useful in industrial settings where durability is essential. Alternatively, there are also self-laminating labels that offer a protective layer, ensuring longevity while maintaining visibility.

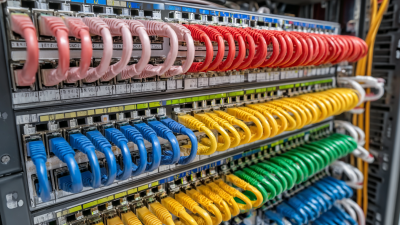

Finally, color-coded labels can be an effective way to identify cable types and connections at a glance. By utilizing a color system, users can quickly differentiate between various cables, making network management more efficient, especially in larger installations. Choosing the right type of Ethernet cable label ultimately depends on your specific networking needs, whether you're looking for flexibility, durability, or quick identification.

When choosing the best Ethernet cable labels for your networking needs, there are several factors to consider. One of the most significant aspects is the material and durability of the labels. Industry reports indicate that labels made from vinyl or polyester tend to offer superior resistance to wear and tear, including exposure to various environmental conditions such as humidity and extreme temperatures. According to a study by the International Organization for Standardization (ISO), high-quality labels can significantly reduce the incidence of misidentified cables, which is critical in maintaining the integrity of network systems.

Another important factor is the ease of use and application of the labels. Labels that come with a self-adhesive backing and are compatible with various printers facilitate quick labeling without the need for additional tools. Research from the Electronic Industries Alliance (EIA) suggests that effective cable management can reduce troubleshooting time by as much as 30%, underscoring the importance of clear and reliable labeling. Additionally, consider labels that provide sufficient space for information, such as cable types or port numbers, to ensure that all relevant details are easily visible and organized. This systematic approach is essential in larger network setups, where the complexity of connections can lead to significant challenges if not properly labeled.

When it comes to labeling Ethernet cables, effective organization can significantly enhance your networking setup. One of the best practices is to use a consistent labeling system that conveys essential information at a glance. Color coding your labels allows for easy identification of different cable types or functions, while clear, concise text can include both the destination and the source of each cable. This practice helps reduce confusion, especially in complex installations.

Tips: Ensure that labels are durable and resistant to wear and tear. Consider using materials such as vinyl or other coating options that withstand environmental factors, which is especially important in commercial networking environments. Also, keep a label printer handy for quick adjustments as your network changes.

Another smart approach is to label both ends of each cable. This way, you can easily trace the connection from the device back to the switch or router without the hassle of visually following the entire path. Additionally, documenting your labeling system through a diagram can further simplify troubleshooting and maintenance tasks, giving you a comprehensive overview of your network layout.

| Label Type | Best Use Case | Durability | Ease of Use | Cost |

|---|---|---|---|---|

| Pre-Printed Labels | For organized installations | Moderate | Very Easy | $ |

| Write-On Labels | Custom labeling on-site | Low | Easy | $ |

| Heat Shrink Labels | Durable applications | High | Moderate | $$ |

| Color-Coded Labels | Quick identification | Moderate | Very Easy | $ |

| Custom Printed Labels | Unique branding needs | High | Moderate | $$$ |

Over time, maintaining and updating Ethernet cable labels is crucial for an efficient networking environment. As businesses grow and evolve, the network infrastructure demands regular refreshing of cable labels to reflect changes. According to a report by the International Data Corporation (IDC), nearly 80% of network issues stem from improper labeling and organization. Regular updates can significantly reduce troubleshooting time, facilitating a more efficient network management process.

When it comes to maintaining your Ethernet cable labels, consistency and clarity are key. Ensure that labels are not only durable but also easy to read. Using a color-coding system can enhance visibility and quick identification of cables, leading to faster resolution of issues. Tips include using laminated labels for longevity and regularly scheduled reviews of the labeling system to accommodate new additions or removals in the network.

It's also advisable to implement a standardized labeling format. This increases overall efficiency and minimizes confusion, especially in larger setups where numerous cables may be intertwined. Regular audits of your labeling system and creating a log of changes can help keep your network documentation up to date, providing transparency and aiding in future troubleshooting and expansions.