When it comes to product labeling, selecting the right plastic label is crucial for ensuring that your items stand out while also conveying important information to consumers. Plastic labels are versatile, durable, and can be designed to meet various aesthetic and functional requirements, making them an ideal choice for many industries. However, with the wide range of plastic materials, types, and printing options available, it's essential to navigate through the numerous choices to find the perfect label that aligns with your product needs.

Understanding the specific requirements for your products is the first step in making an informed decision about plastic labels. Factors such as the environment where the labels will be used, the type of information to be displayed, and the expected longevity of the label should guide your selection process. Additionally, considering the visual appeal of the label can significantly impact consumer perception and brand recognition.

Ultimately, the right plastic label not only serves the practical purpose of providing necessary information but also enhances the overall presentation of the product. By examining the available options and aligning them with your product specifications, you can make a strategic choice that supports both function and aesthetic appeal, ensuring that your labels meet the demands of your business and resonate with your target audience.

When selecting plastic labels for your products, several critical factors should be considered to ensure they meet your needs effectively. Material choice is fundamental, as plastic labels can be made from various polymers, including polyethylene and polypropylene. According to a report by Smithers Pira, the global market for plastic labels is expected to reach $34 billion by 2024, indicating the growing demand for durable and versatile labeling solutions. The type of environment where the labels will be used is also crucial; for instance, labels exposed to moisture or chemicals should use materials that can withstand these conditions without fading or peeling.

Another vital factor is the printing method. Various techniques, such as thermal transfer, digital printing, and flexographic printing, offer different advantages in terms of durability and color vibrancy. A study by the Label and Narrow Web magazine highlights that brands report a 20-30% increase in customer retention when employing high-quality labeling. Additionally, consider the adhesive type; permanent adhesives are great for long-lasting applications, while removable adhesives can be suitable for temporary labeling needs. Ultimately, by understanding these considerations, companies can choose plastic labels that enhance their products’ visibility and functionality, aligning with both branding efforts and logistical requirements.

This chart illustrates the key factors to consider when selecting plastic labels for your products. The factors measured include Durability, Cost, Weather Resistance, Customizability, and Eco-friendliness, depicted in percentage ratings from 0 to 100.

When selecting plastic labels for your products, it’s essential to consider the various types of plastic materials available and their unique properties. One of the most commonly used plastics for labeling is polypropylene (PP), which is known for its excellent resistance to moisture, chemicals, and tearing, making it ideal for outdoor and industrial applications. According to a report by Freedonia Group, the demand for plastic labels is projected to reach over $43 billion by 2025, driven significantly by the versatility of materials like PP.

Another popular choice is polyethylene (PE), which is lighter than polypropylene and offers good durability but may not withstand harsher chemicals as well. PE labels are often utilized in food packaging due to their ability to be heat-sealed and their compliance with food safety standards. A study by Smithers Pira highlights that sustainability trends are pushing manufacturers to explore biodegradable variants, such as polylactic acid (PLA), which is derived from renewable resources and is gaining traction in eco-friendly labeling solutions. The growing preference for sustainable materials indicates a significant shift in the industry, demonstrating the importance of selecting appropriate plastic types based on end-use requirements.

When selecting the right plastic label for your products, it's crucial to consider the compatibility of the labels with various surfaces and materials. According to a report by the Label Manufacturers Association, over 80% of label failure is due to improper adhesion. This highlights the importance of matching the label material and adhesive to the product's surface, whether it's glass, metal, or plastic. For example, polyolefin labels are suitable for containers that experience extreme conditions, such as high moisture or temperature, while polyester labels provide better durability against chemicals and abrasions, which is essential for industrial applications.

Moreover, the choice of label type should also align with the product's life cycle. A study by the Flexible Packaging Association revealed that nearly 60% of consumers prefer sustainable packaging. Thus, using biodegradable labels on eco-friendly products can enhance brand image and consumer trust. Additionally, pressure-sensitive labels can effectively adhere to curved surfaces often found in cosmetic packaging, ensuring that branding remains intact and visible. Understanding these compatibilities not only aids in the selection process but can also significantly impact product presentation and overall customer satisfaction.

When it comes to printing methods for plastic labels, several techniques are commonly employed, each with its own set of advantages and ideal applications. One of the most prevalent methods is digital printing, which allows for high-quality images and vibrant colors. This method is particularly beneficial for short runs and custom designs, as it eliminates the need for extensive setup and plate-making processes. Digital printing on plastic labels is also efficient for variable data printing, such as barcodes or QR codes, making it a versatile choice for modern labeling requirements.

Another method to consider is flexographic printing, known for its speed and efficiency in producing large quantities of labels. Flexographic printing uses flexible relief plates, allowing for a wide range of substrates, including various plastics. It's particularly well-suited for long runs where uniformity in color and design is crucial, such as for consumer goods and packaging. Moreover, flexographic printing can accommodate eco-friendly inks, making it an attractive option for businesses aiming to adopt sustainable practices.

Lastly, screen printing is a robust choice for plastic labels requiring durability and resistance to harsh conditions. This method involves pushing ink through a mesh screen, which can create thick and vibrant designs. Screen printing is ideal for labels that will be exposed to outdoor elements or chemical substances, as it provides excellent adhesion and longevity. Each of these methods has its unique strengths, and selecting the right one depends on your specific product needs and the intended application of the labels.

| Label Type | Material | Printing Method | Durability | Cost |

|---|---|---|---|---|

| Vinyl Labels | PVC | Digital Printing | 5-10 years | $0.15 - $0.50 each |

| Polyester Labels | PET | Flexographic Printing | 5-8 years | $0.20 - $0.60 each |

| BOPP Labels | Biaxially Oriented Polypropylene | Screen Printing | 3-5 years | $0.10 - $0.40 each |

| Static Cling Labels | Static Cling Vinyl | Inkjet Printing | 1-2 years | $0.05 - $0.25 each |

| PP Labels | Polypropylene | Thermal Transfer | 3-5 years | $0.12 - $0.45 each |

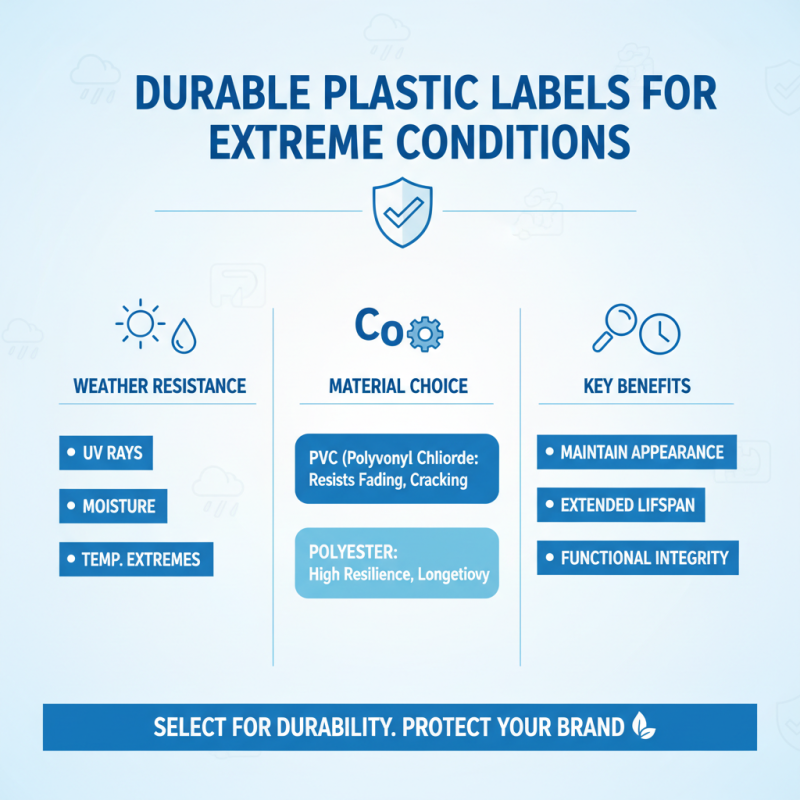

When selecting plastic labels for your products, durability and weather resistance are paramount considerations. Labels that will be exposed to outdoor elements must withstand various environmental conditions, including moisture, UV rays, and extreme temperatures. Therefore, choosing materials like polyvinyl chloride (PVC) or polyester can be advantageous, as these plastics are known for their resilience against fading, cracking, and peeling over time. It is essential to assess the specific environmental factors that your labels will encounter to ensure they maintain their appearance and functionality throughout their intended lifespan.

Additionally, the printing technology used on labels can affect their durability. Certain inks are designed to resist fading and wear, making them suitable for outdoor use. When selecting labels, it’s crucial to consider not just the label material but also the ink and adhesive quality. An adhesive that can withstand humidity and temperature fluctuations will help ensure that labels remain adhered to surfaces over time, further enhancing their effectiveness. By carefully evaluating these components, you can select the right plastic label that meets both aesthetic and functional needs while ensuring longevity in diverse conditions.