In today's fast-paced business landscape, selecting the right Barcode Roll can significantly impact operational efficiency and inventory management. As more businesses recognize the importance of precise labeling and data tracking, the demand for specialized barcode solutions is projected to soar. According to a recent report by MarketsandMarkets, the global barcode market is expected to reach $60 billion by 2025, indicating a growing trend that companies cannot afford to overlook.

Industry expert Dr. Emily Tanner, a leading authority in barcode technology, emphasizes the importance of making an informed choice, stating, “Choosing the right Barcode Roll is critical; it can streamline your supply chain and drive accuracy in your data management.” With the myriad options available, organizations must consider factors such as durability, compatibility with printing systems, and the specific requirements of their business operations.

As we delve into the "2025 Top 5" Barcode Rolls, we aim to equip businesses with the knowledge and insights necessary to make the best choice. By understanding key features and analyzing market trends, businesses can thrive in their respective industries and leverage barcode technology for enhanced productivity and efficiency.

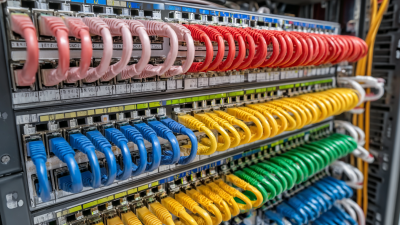

When selecting the best barcode roll for your business, it's essential to understand the various types available in the market. Barcode rolls come in different sizes, materials, and finishes, each suited for specific applications. The most common types include direct thermal, thermal transfer, and pre-printed labels. Direct thermal rolls are ideal for short-term labeling, such as shipping labels, while thermal transfer rolls offer durability and longevity, making them perfect for items that require extended tracking.

Tip: Always consider the environment in which your labels will be used. For instance, if the labels will encounter moisture, opting for waterproof materials is advisable to maintain the integrity of the barcode.

Additionally, businesses should evaluate the printing technology they use. Some printers are compatible only with specific types of rolls, which can affect both the quality and the efficiency of printing. It’s vital to align your barcode roll choice with your existing equipment to avoid compatibility issues.

Tip: Before purchasing, ask for samples from suppliers to test with your printer and ensure they meet your needs regarding print quality and adhesion. This will save time and resources in the long run.

When selecting the right barcode roll materials for your business, there are several key factors to consider that can significantly impact efficiency and accuracy in operations. Firstly, the type of adhesive used in the barcode roll is crucial. According to a 2021 study by the Association for Automatic Identification and Mobility (AIM), around 30% of barcode scanning failures are attributed to poor adhesion. Therefore, choosing a durable adhesive that can withstand various environmental conditions while maintaining its integrity is essential for optimal performance.

Another vital aspect is the material composition of the rolls. Reports from the Barcode Network indicate that synthetic materials, such as polypropylene and polyester, are often preferred for their resistance to moisture and tearing, especially in industrial settings. In contrast, paper-based rolls may be suitable for indoor applications but can lead to higher rates of damage when exposed to the elements. Additionally, businesses should consider the printing method, as thermal transfer versus direct thermal requires different roll types. Selecting the right combination based on these factors will ensure that the barcode rolls meet the operational demands and maintain high-quality standards throughout their usage.

When selecting the best barcode roll for your business, understanding the impact of size and dimensions is crucial. The width and length of barcode labels can affect not only the readability but also the efficiency of your scanning processes. Larger labels may provide more space for additional information, but they can also lead to wasted material if not properly sized for the product. Conversely, smaller labels might fit onto compact items, yet they may require more sophisticated scanning equipment due to potential misreads.

Moreover, the orientation of the barcode plays a significant role in operations. A vertically oriented barcode might be more suitable for tall products, while a horizontally oriented one could be better for wider packaging. Choosing the right dimensions not only enhances scanning accuracy but also streamlines your inventory management and logistics processes. Therefore, it’s essential to evaluate your product sizes, scanning hardware, and workflow requirements when deciding on barcode roll specifications to optimize your operations effectively.

| Roll Size (Inches) | Label Dimensions (W x H, inches) | Core Size (Inches) | Count per Roll | Best Use Case |

|---|---|---|---|---|

| 2.25 | 1 x 2.625 | 1 | 500 | Retail Pricing |

| 4 | 2 x 4 | 1.5 | 250 | Shipping Labels |

| 6.75 | 3 x 1 | 3 | 200 | Warehouse Inventory |

| 8 | 4 x 6 | 3 | 100 | Product Packaging |

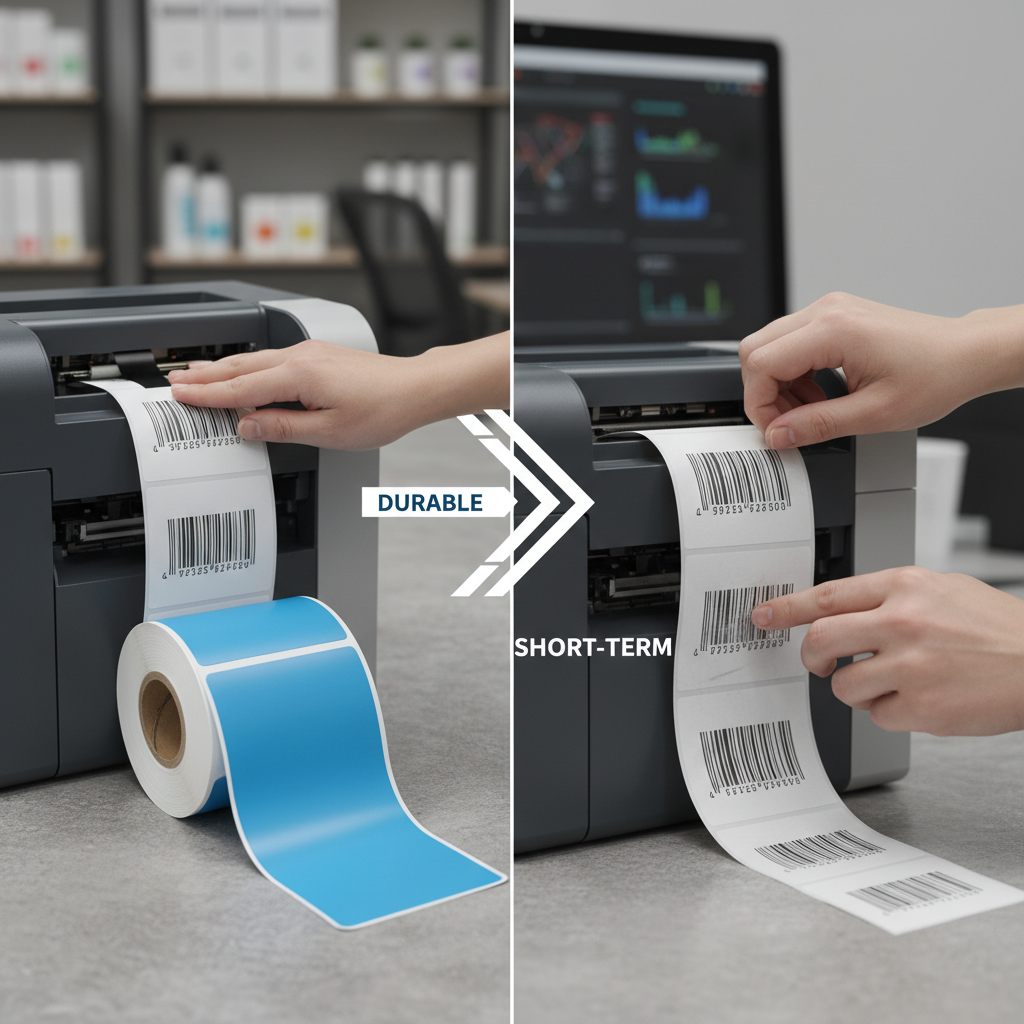

When selecting the right barcode rolls for your business, it’s crucial to understand the difference between thermal transfer and direct thermal printing methods. According to a report by Technavio, the global barcode printer market size is expected to grow by approximately $1.65 billion from 2021 to 2025, highlighting the growing importance of efficient barcode solutions in various industries.

Thermal transfer printing uses a ribbon to transfer ink onto the label, which results in a durable and long-lasting print that is resistant to heat, chemicals, and moisture. This makes it an ideal choice for items that require high durability, such as shipping labels or inventory management applications.

On the other hand, direct thermal printing generates images by applying heat directly to the thermal paper, eliminating the need for ribbons. This method is often favored for its simplicity and speed, particularly in environments like retail and logistics. Industry data indicates that around 60% of businesses prefer direct thermal printers for standard label applications because of their lower ongoing costs and less maintenance than thermal transfer printers. However, direct thermal labels are more susceptible to fading and damage, which can be a significant factor for businesses that require long-term barcoding solutions.

Understanding these differences is crucial to making an informed decision for your specific barcode needs.

Maintaining your barcode rolls is crucial for ensuring optimal performance and longevity. Routine maintenance can significantly impact the lifespan of your rolls and the efficiency of your barcode scanning process. Firstly, store your barcode rolls in a cool, dry place away from direct sunlight to prevent any damage to the adhesive and the ink. Exposure to extreme temperatures can cause the materials to warp or degrade, leading to poor scans and wasted inventory.

Another key aspect of maintenance is regularly checking for signs of wear and tear, such as smudging or fading. If you notice these issues, it’s advisable to adjust your printing settings or consider changing your printer's ink to maintain quality. Additionally, cleaning the printer heads after every few rolls can help prevent build-up, ensuring that each scan is precise and accurate.

Tips for Optimal Care: