Choosing the right thermal ribbon roll is crucial for achieving high-quality prints in various applications, whether it be for labels, barcodes, or other printing needs. The right ribbon can significantly affect the durability and clarity of the printed material, making it essential to understand the different types available and their specific uses. With a multitude of options on the market, selecting the perfect thermal ribbon roll can seem overwhelming, yet it can greatly enhance productivity and efficiency in printing processes.

Various factors come into play when making this decision, including the type of printer being used, the surface material of the items being printed on, and the environmental conditions in which the prints will be exposed. Additionally, understanding the differences between wax, resin, and wax-resin thermal ribbon rolls is vital for ensuring that the printouts meet the required standards for longevity and resistance to wear.

This guide aims to simplify the selection process by providing insights into the essential considerations for choosing the right thermal ribbon roll that aligns with your unique printing requirements. With the right knowledge, you can make an informed decision that will lead to improved print quality and satisfaction in your printing endeavors.

When selecting the right thermal ribbon roll for your printing needs, several key factors must be considered to ensure optimal performance and quality output. One of the most critical factors is the type of material being printed on. Different surfaces, such as paper, synthetic materials, or textiles, require specific ribbon types to achieve the best results. For example, wax ribbons are best suited for standard paper labels, whereas resin ribbons offer superior durability and are ideal for synthetic materials that require resistance to heat and chemicals. According to industry reports, using the appropriate ribbon type can result in up to a 40% increase in print quality, significantly reducing the number of reprints and wastage associated with poor-quality labels.

Another essential consideration is the print speed and environment in which the printer operates. Faster print speeds can lead to more friction and heat, necessitating a ribbon that can withstand these conditions without compromising print quality. Additionally, the printing environment—whether it involves exposure to moisture, temperature fluctuations, or aggressive handling—should influence the choice of ribbon. Studies indicate that using the wrong thermal ribbon in challenging conditions can lead to a 50% increase in print head wear, affecting overall printer longevity and maintenance costs. By carefully evaluating these factors, businesses can ensure they select the most suitable thermal ribbon roll to maximize their printing efficiency and reliability.

When selecting a thermal ribbon for your printing needs, understanding the various materials available is crucial. Thermal ribbons primarily fall into three categories: wax, resin, and wax-resin. Each material offers distinct advantages and is suited for specific applications. Wax ribbons are typically the most economical choice, making them ideal for short-term applications where cost-effectiveness is a priority. These ribbons produce good quality prints on uncoated paper and are commonly used for shipping labels and name tags.

On the other hand, resin ribbons are designed for durability and are excellent for printing on synthetic materials such as polyester and polypropylene. They provide high resistance to heat, chemicals, and abrasion, making them a perfect fit for products that require longevity and robustness in outdoor or challenging environments. For users seeking a balance between the affordability of wax and the durability of resin, wax-resin ribbons offer a versatile solution. They combine the advantages of both materials, delivering decent durability while still being cost-effective, making them suitable for a wide range of applications, from barcodes to high-quality label printing.

| Ribbon Type | Material Composition | Durability | Best Use Cases | Print Quality |

|---|---|---|---|---|

| Wax | Made primarily of wax | Medium durability | Shipping labels, general-purpose labels | Good print quality |

| Resin | High percentage of resin | High durability | Outdoor labels, chemical labels | Excellent print quality |

| Wax-Resin | Blend of wax and resin | Good durability | Product labels, barcode labels | Very good print quality |

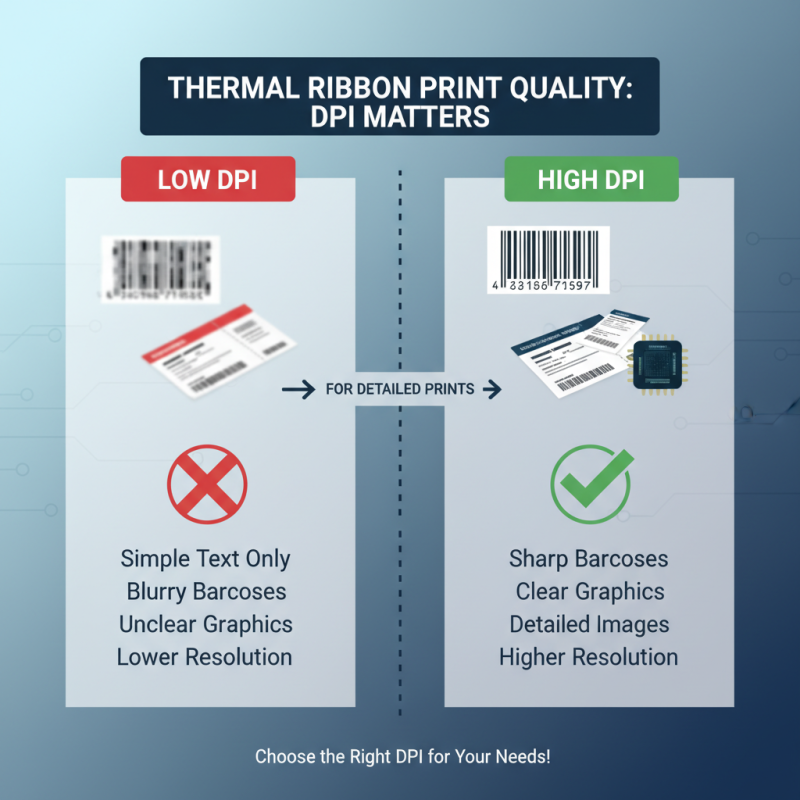

When evaluating print quality for thermal ribbon rolls, understanding DPI (dots per inch) requirements is crucial. DPI measures the resolution of the printed image; higher DPI values result in sharper and clearer prints. For instance, if your application involves printing barcodes, shipping labels, or any detailed graphics, it's essential to select a thermal ribbon that supports the required DPI for those specific tasks. Low DPI might suffice for simple text printing, but for intricate designs and high-resolution images, ensure the ribbon can deliver the necessary detail without smudging or blurring.

Additionally, ribbon compatibility plays a significant role in achieving optimal print quality. Different thermal printers may require specific ribbon types or sizes that correspond with their capabilities. It's vital to check the specifications of your printer and select ribbons that match both the machine's requirements and the intended print resolution. Using an incompatible ribbon can lead to poor performance, resulting in faded prints or damage to the equipment over time. By prioritizing the right DPI settings and ribbon compatibility, users can significantly enhance their printing outputs, ensuring they meet the highest quality standards for their projects.

When selecting thermal ribbon rolls for your printing needs, understanding the appropriate width and length is crucial for optimizing performance across different printer models. Industry standards indicate that most thermal printers operate effectively with ribbon widths ranging from 1 inch to 8 inches, with a majority falling between 2 and 4 inches. This range accommodates a variety of applications, from barcode printing to shipping labels. According to the latest market research, the thermal transfer ribbon market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026, underscoring the importance of selecting the right ribbon dimensions to match the increasing demand for efficient printing solutions.

Length consideration also plays a critical role in ribbon selection. Typical ribbon lengths range from 100 to 450 meters, with 300-meter ribbons being the most common for high-volume printing environments. A report from Smithers Pira shows that the choice of ribbon length can significantly impact workflow efficiency; shorter ribbons may require more frequent replacements, which can disrupt production speed. Conversely, longer ribbons allow for extended printing periods, reducing downtime. Thus, understanding the dimensions of your thermal ribbon rolls in conjunction with your specific printer model ensures that you achieve the best printing quality while maximizing operational efficiency.

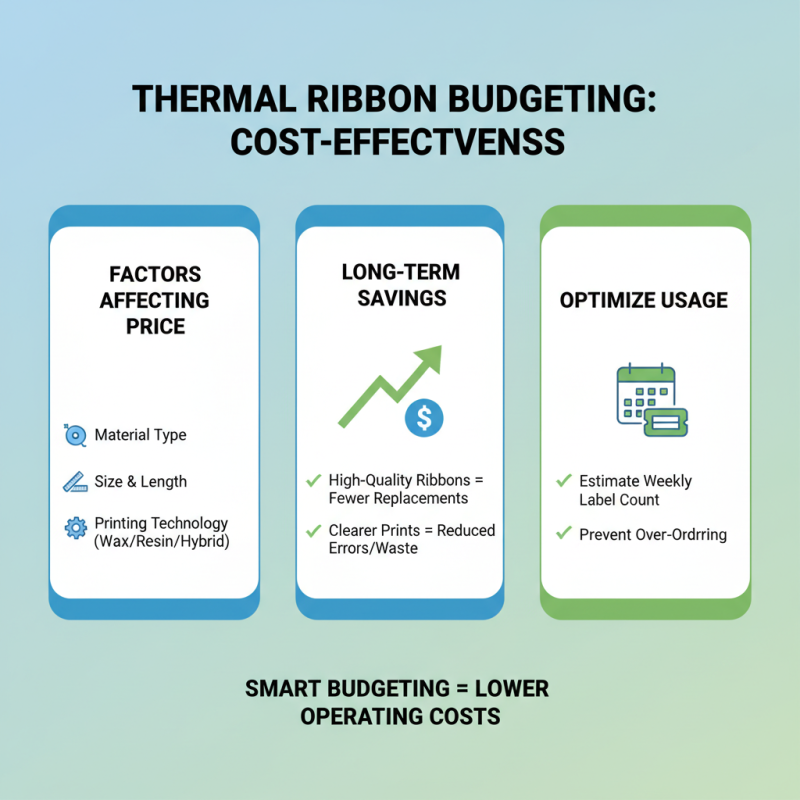

When it comes to budgeting for thermal ribbons, understanding their cost-effectiveness is essential. Thermal ribbons vary in price based on factors such as material, size, and printing technology. Generally, investing in high-quality ribbons can lead to lower long-term costs as they are often more efficient, providing clearer prints and reducing the frequency of replacements. Estimating your usage can significantly affect your budget; knowing how many labels you print weekly can help guide your purchase decisions and prevent over-ordering.

Tips for budgeting effectively include considering bulk purchasing options, which can lower the cost per roll. Also, keep track of your consumption rates and adjust your orders accordingly. It's wise to compare prices from various suppliers, as slight differences can significantly impact your overall budget. Moreover, consider the potential waste produced by lower-quality ribbons that may not print efficiently, as this could lead to increased expenses. Using a consistent supply can also help streamline management and predict future needs more accurately, making budgeting simpler.